Then we instantiate a Servo object instance named myServo. We first include the Servo library header. Int angle = 0 // store the current angle void setup()

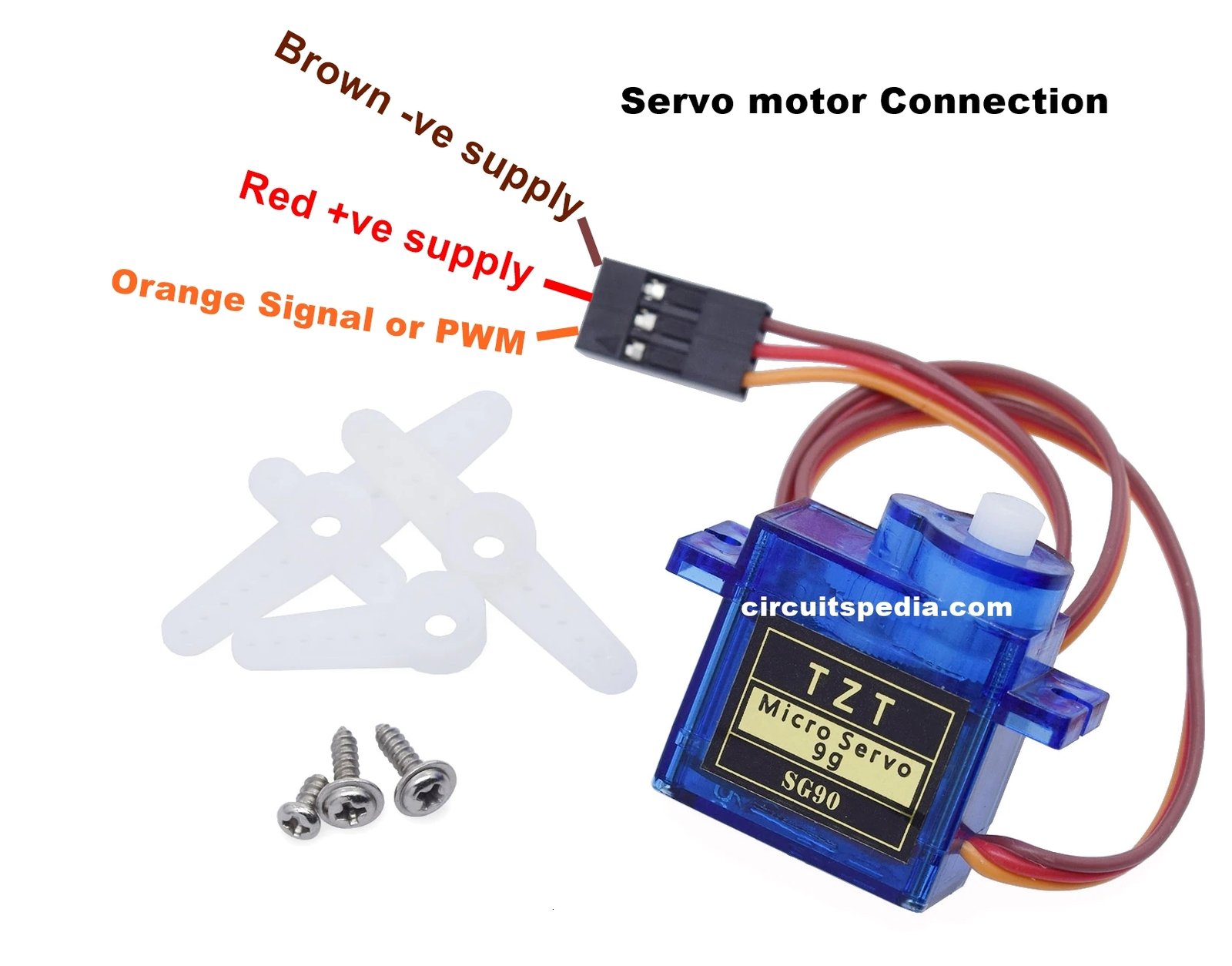

Servo myServo // instantiate the Servo object Here is a firmware that provides a cyclic movement from 0 degrees to 180 degrees. It is connected to one of the PWM inputs of the Arduino.įirmware for controlling one servo using the Servo library The red and brown wires are connected to the Vcc and Ground respectively.

Servo motor arduino pin full#

Therefore, if your servo motor is not turning to the full range of motion which you expect, try either reducing the minimum or increasing the maximum pulse width in microseconds using the servo.attach(pin,min,max) function.A servo motor has 3 output wires. In fact, in my experience, even within the same make and model of servo motors, these max and min pulse widths differs slightly as well. However, these values are not always true for every make and model of the servo motor you bought. We can see that the minimum pulse width that corresponds to the 0 ° position defaults to 544, while the maximum pulse width that corresponds to the 180 ° position defaults to 2400. Max (optional): the pulse width, in microseconds, corresponding to the maximum (180-degree) angle on the servo (defaults to 2400) Min (optional): the pulse width, in microseconds, corresponding to the minimum (0-degree) angle on the servo (defaults to 544) Pin: the number of the pin that the servo is attached to attach() function, we see the following: Syntax The Servo library allows us to easily control the motor position in degrees by converting the degrees we specify into the microseconds of the pulse width required to "tell" the servo motor which angle to turn to. Step 3: Calibrating the ServoĪ servo motor uses pulse width modulation (PWM) to understand which position the servo motor should turn to.

Servo motor arduino pin code#

Find out more hereĪnd thats all the code you need to control the servo however you want! However, if your realized that your servo motor is not rotating the full range of motion of 180 °, you might need to calibrate your servo at the next step.

0 kommentar(er)

0 kommentar(er)